Mold materials and documents for quotation

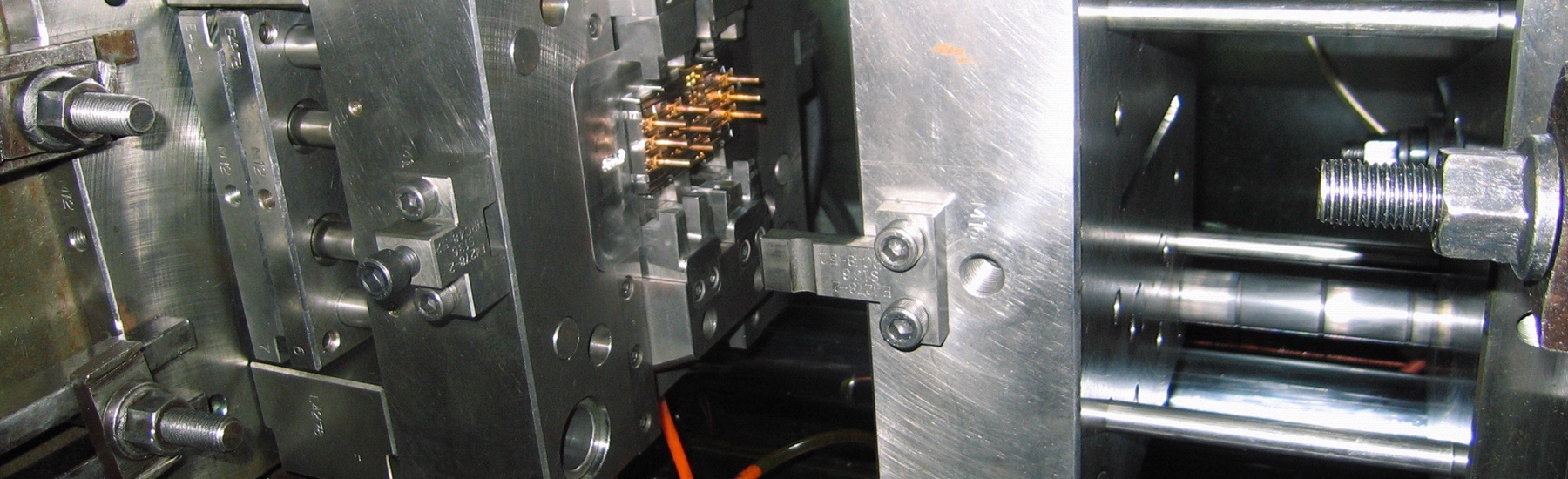

The injection molds provided by GSF are compatible with customers machines. Mold cavities and cores are made of hardened, pre-hardened or stainless steel, according to product criteria and required life cycle. Please refer to the list below when enclosing information for mold quotation.

- 3D file in STEP (preferred) or IGES format (essential information)

- Connections with the machine: Water fitting thread, sprue bushing radius, locating ring diameter, ejector bar thread and lift ring thread (essential information)

- Estimate of the required mold life (important information)

- Number of cavities (important information)

- 2D drawing indicating tolerances, surface finishes, plastic material and location of the injection gate (recommended information)

Lead time and mold modifications

We can usually deliver the samples to our customer in 6 weeks. We will make the modifications in China in case of some design changes needed. After customer has approved the samples, we will arrange the transport and customs clearance to Finland or Estonia depending on the customer requirement. Normally we arrange the transport by sea freight. In urgent cases we make the first batch plastic parts in China. We can also transport the molds by courier if they are needed in Finland urgently.